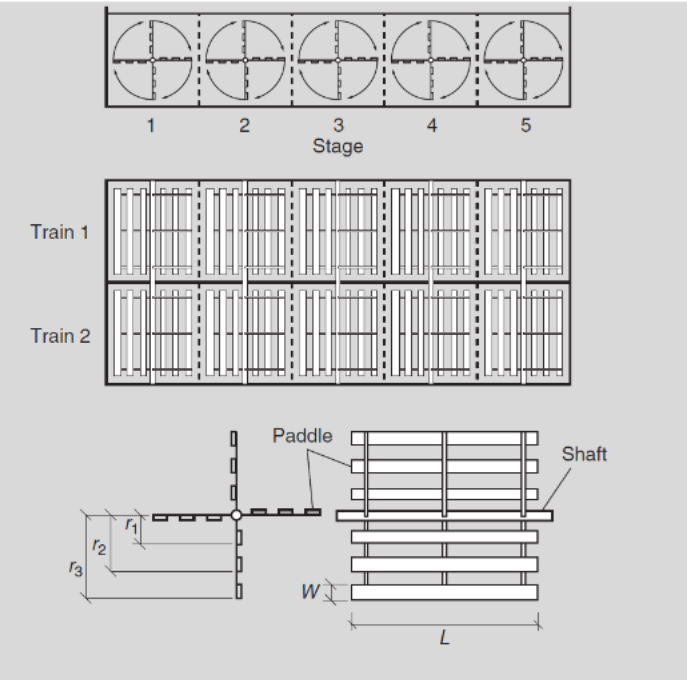

Top view of the unit showing 2 parallel trains and each train is to be made of 5 wheels compartments in series. Top Bottom left.

Horizontal Shaft Paddle Wheel Flocculators Are To Be Chegg Com

CD Coefficient of drag A Paddle area ft2 m2 ρ density of the liquid ρ γg v Velocity of the paddle relative to water fps mps g gravity 3217 ftsec2 981 ms2 Table 83 gives values for drag coefficient.

. For the rapid mixer the velocity gradient C is 850 s with a detention time of 120 s. Design of Rapid mixing Coagulation CHAPTER. MRIs horizontal paddle wheel flocculators consist of stainless steel shafts structures and paddles.

Shafting and paddle supports - epoxy coated carbon steel chroming or 304316 SS. Practical Design Issues When it comes to the practical design of coagulation and flocculation facilities designers must consider four process issues. Paddle Wheel Flocculator Design.

Figure 34 Horizontal Paddle Flocculator Design An 2017 Bottom left. Paddle wheel flocculator design Portray the midnight with dark midnight blue along with some smoky grey in excess of it portraying clouds with these stars peeping out and using studs to produce constellations is just so excellent. Amwell flocculators are available in your choice of horizontal or vertical configurations for all water applications.

Unit Operations and Processes in Environmental Engineering. Bilge Alpaslan Kocamemi. Horizontal flocculator drives can have a dry well requiring a wall penetration or a wet well arrangement.

Cross section and close up of each wheel showing each one has 4 arms with 3 paddle boards on each arm. FLOCCULATOR 3 1 2 Q HLG 144 f 2 t n. Horizontal Paddle Wheel Flocculators Hydraulic Flocculation Important Design Features in Flocculation Problems and Discussion Topics References.

1 the type and. For flocculation the average velocity gradient C over two sections is as s with a time-velocity gradient GO of 97500. 11 Tapered flocculation may be obtained by varying.

Configurations and Materials of construction include. Paddle Wheels Design The power imparted by paddle wheels is given by the following. Patented design opens to allow automated cleaning by MRI Sludge Collector.

Amwell paddle wheel flocculators provide engineers and water treatment facilities with well designed well crafted flocculator systems engineered for long life and minimal maintenance. A tank-impellor type rapid mixer and a horizontal-paddle wheel type flocculator are needed to treate design flow of 5000 mºd. The paddle size the number of paddles diameter of the paddle wheels on the various horizontal shafts the rotational speed of the various horizontal shafts 46 Ref.

On each paddle wheel having a common horizontal shaft. Flocculator Design Overview Analysis of hydraulic flocculators Ratio of maximum to average energy dissipation rate Inefficiency of energy use due to nonuniformity of energy dissipation rate The great transition at Ø 55 Flocculator Design Head loss collision potential residence time. PWS Publishing Company 1996.

2 2 3 v3 g C A v P CDA D γ. Paddle and hydraulic mixers and the option of mixing flocculator styles.

Paddle Wheel Flocculators Vs Impeller Flocculators Jms

Flocculation Paddle Wheel Type Flocculator Service Provider From Delhi

Horizontal Paddle Wheel Flocculator Jms Mega Floc Hpwf

Paddle Wheel Flocculators Jms Mega Floc

Solved Horizontal Shaft Paddle Wheel Flocculators Are To Be Chegg Com

0 comments

Post a Comment